Cutting Trials

Cutting Trials for web-based material

- Cut edge quality

- Welding of cutting edges

- Solid fiber bump cut

- Angel hair

- Fuzz occurrence

- Delamination

- Product flow issues

- Comparison to guillotine cutter results

Benefit from improved cutting quality, higher production speed and less quality claims

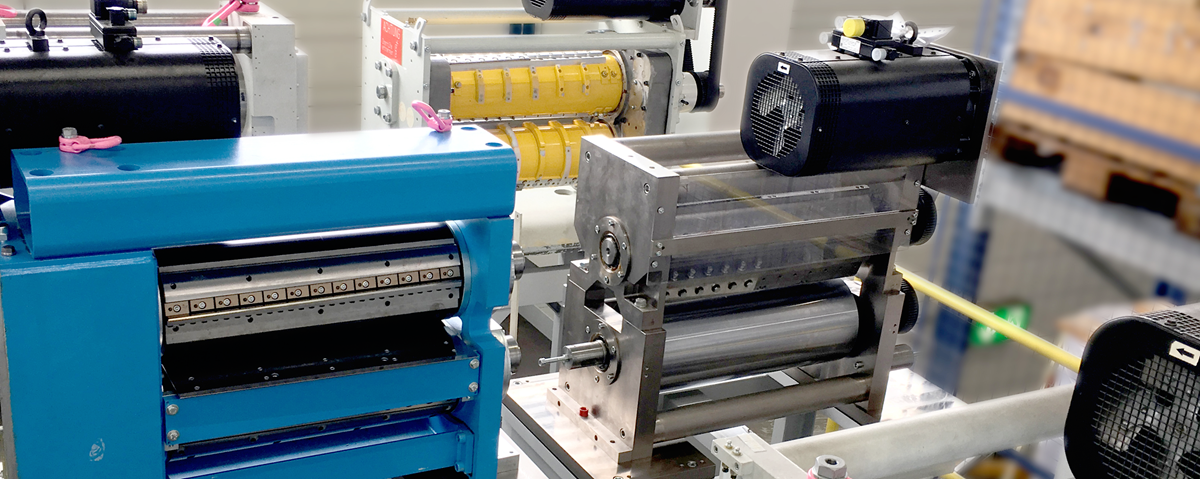

Inhouse Lab Sheeter for professional cutting trials

On our in-house Lab Sheeter, located in Hamburg, Germany, we offer a series of flexible and scientific tests with statistical and optical evaluation of the results. The in-house Lab Sheeter is part of the R&D equipment at BW Papersystems and is especially designed to execute professional cutting trials for any kind of web-based test material. Whenever you experience issues with cut quality or would like to test a new substrate for your production process, BW Papersystems can perform the required cutting trials. The experienced R&D team has all the expertise in analyzing the required knife geometry as prerequisite to improve the cut quality of the respective material. With cutting trials we reproduce occurring issues, being the basis for improvements of the knife geometry.

Several cross-cutter cartridges available

Due to the high flexibility of the Lab Sheeter, several cross-cutter cartridges with any type of knives, and conventional cross-cutters with fixed knives, can be tested. The cut quality can be analyzed according to XEROX or your individual standard. You don’t not need to interrupt your production in order to perform cutting trials. The required amount of test material is very low as the BW Papersystems Lab Sheeter runs with a reel width of 230mm which can represent any working width of the individual sheeter.

Considering switching from guillotine to rotative sheeting?

A rotary sheeter will not only increase your output tremendously, it also erases intermediate steps. From the roll to stack or ream in one process. By buying rolls instead of sheets, you will also lower your costs.

- Foils in layers (sandwich material)

- Composites of different materials (paper, plastic, metal, etc.)

- Materials for the renewable energy industry

- Foils, including adhesive foil and metail foil

- Glass fabric / Carbon fabric

- Filter material

- Medical materials, e.g. medical pads

- Fabrics

- Wood coating / Veneer

- Any material on a roll that can be cut with a rotary knife…

BW Papersystems Overview

BW Papersystems, a division of Barry-Wehmiller, combines strong brands, innovative technologies, and long-standing experience to create industrial paper converting machines and equipment for the sheeting and packaging, stationery, book binding, security documents, and corrugating and finishing industries.

Watch VideoFind your Technician

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

I very much like the ability to sharpen the knife inside the machine. It saves a lot of time, especially with the material we run on the eCon sheeter.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

a2a25e0f-43cd-43f0-9c3f-a5cc11fbcc29.jpg?sfvrsn=4dd9e7f_1)

359d5a13-484b-4d53-ac6f-d25f42158726.jpg?sfvrsn=c8dd9e7f_1)

.jpg?sfvrsn=a0dd9e7f_1)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)