TAPPI and MarquipWardUnited, 100+ Years of Corrugated Packaging Excellence

Congratulations to TAPPI on 100 years of service and technological improvements to the paper and converting industries. Marquip, Ward Machinery and United Container Machinery companies have been proud to work alongside TAPPI, providing support and leadership to the industry. Today MarquipWardUnited is the longest continuous supplier of corrugated equipment in the world. Over the past century, MarquipWardUnited has revolutionized the corrugated packaging industry.

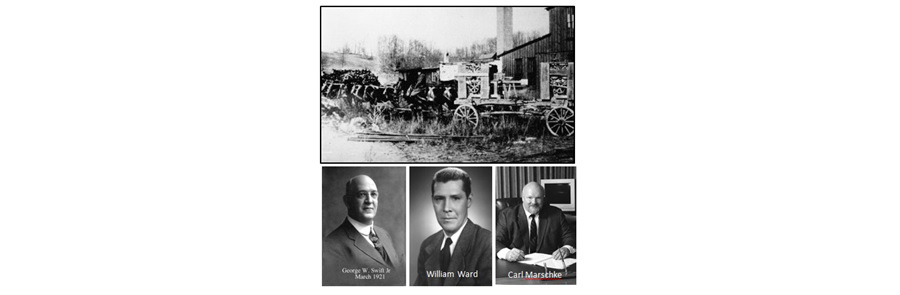

MarquipWardUnited’s wet end technologies can trace its roots to inventors like Francis X. Hooper and George W. Swift. In 1882, these men developed corrugated machinery, which changed the world of packaging. Historic achievements include landmark patents in fingerless singlefacer technology (1930s), multiple quick flute change singlefacers (1940s) and interactive corrugator process control systems (1960s). Marquip, founded on the creativity of Carl Marschke and Richard Thomas changed the world of corrugated packaging forever. Innovations of high-speed splicers, helical-blade cutoff knives, and precision slitter/scorers moved corrugator performance to new unimaginable levels. Ward Machinery Company started when William Ward developed the Rotary Die Cutter, an invention that brought with it tremendous packaging flexibility at amazing speeds.

MarquipWardUnited has been awarded well over 100 patents. Following are the top 8 MarquipWardUnited innovations that have created tremendous progress for the Corrugated Packaging Industry in the last 100 years.

#8 High-Shear Starch Mixing Systems

In 1980, two innovative pioneers Keith Sickafoose and Hernan Jamarillo developed the concept of high-shear starch mixing. The successful commercial implementation of the high-shear starch mixing system was led by Dave Stotler of what became VortX. The technological breakthrough of high-shear mixing allowed corrugators to run much faster with lower starch application rates, higher bond strength and significantly lower costs.

Today VortX is a member of the MarquipWardUnited family. The VortX Tornado Systems features smaller batch production. Small batches are mixed with precision to create the optimal starch for each application with recipes tailored to the corrugator production requirements. Fully automatic operation provides process repeatability and adhesive consistency. VortX innovation continues with the recent LaserSteinTM, fully-automatic starch viscosity monitoring system.

#7 Gun-Drilled, Low-Inertia, InfusionTM Doublefacer Hot Plates

United Container pioneered the concept of the high-efficiency, gun-drilled hot plate. Prior, cast iron steam chests deflected heat causing inefficient heat transfer and web crushing. The revolutionary heat-stabilized geometry of the thin, gun-drilled plate allows little or no cross-machine plate deflection. This provides for uniform heating across the machine width. Run speeds are significantly increased as is board caliper. Low thermal inertia allows plates to adjust surface temperatures quickly and effectively to match any grade of board. With over 3,000 gun-drilled hot plates operating in corrugated plants today, this technology is a proven performer.

#6 Doublefacer Vacuum Traction Section (VTS)

MarquipWardUnited’s unique patented vacuum traction section was originally developed as part of the Pyro Beltless Doublebacker with Larry Hamm of Willamette Industries. This was the first machine allowing production of corrugated board without a corrugated belt. Later the features of the very flat United InfusionTM hot plates were combined with the Vacuum Traction Section (VTS) to create the Cool-Vac doublefacer. The VTS draws moisture through the bottom liner balancing the top and bottom to create exceptionally flat board with improved flexural stiffness and no crush. It was discovered that the corrugated sheets produced by this machine can be converted without curing time. This reduces a plant’s work-in-process inventory and associated costs. In the converting department cooler, flatter, stiffer corrugated sheets, results in greater throughput with fewer converting machine stoppages and significantly reduced waste.

#5 Thin-Blade Slitting

Marquip introduced Thin-Blade Slitting with the Razorset® Slitter/Scorer in 1989. Razorset® quickly revolutionized slitting of board by improving the slit edge quality and reducing dust creation on the corrugator. The open, square clean board edge allowed conversion machinery to feed blanks more reliably. The uncrushed edge also enhanced box print flexibility and performance. The patented system with rotating anvil allowed the ability to trim down to ¼” per side…a huge savings over the shear-type tooling that was common at the time.

#4 Helical-Cylinder Direct-Drive Cutoff Knife

Marquip was the first to introduce the helical knife with multiple drive motors. The use of a low inertia knife cylinder and the cluster motor concept allowed the cutting of even the shortest sheets at high corrugator speeds, alleviating a significant constraint on corrugator productivity. Today’s line of cutoff knives continues that tradition with recent developments that have led to new and improved knife bar designs. They offer the longest blade tune cycle available, low power consumption using the latest technologies in motor and drive design, and low noise emissions for a user-friendly environment.

#3 High-Speed Splicing

Marquip introduced the Tailgrabber Web Splicer in 1975. It was the very first splicer capable of splicing medium at 650 FPM. This may not seem fast now, but in those days it was quite revolutionary – about four times as fast as existing machines! This splicer introduced the tail-grabbing feature that allowed the paper to be entirely utilized off the roll core. Since then more than 5,000 splicers have been installed. Along with speed, came incredible reliability. The current world record of 4,082 consecutive, successful splices was set by Jean Carlo Cerdas of New England Sheets (July 15, 2014).

#2 The Fingerless Singlefacer

Swift first patented the fingerless singlefacer in the 1930’s. This early innovation brought with it tremendous gains in corrugator productivity, board quality and reliability.

Today, the evolution of the singlefacer is the Vanguard. It is the industry standard in pressure roll-style singlefacers. A vertical roll stack alignment of large diameter corrugated rolls (407 mm) and pressure roll (500 mm) makes runnability smooth and reliable at all operating speeds. The Vanguard’s large diameter roll design has a proven track record of long useful life and low cost of ownership. In North America, there are Vanguards that have achieved over 980,000,000 lineal feet of useful corrugated roll life before a regrind.

#1 Rotary Die Cutter

Perhaps no machine innovation has impacted the corrugated industry as much as the Rotary Die Cutter. In 1962, William Ward and one helper built the first commercially successful Rotary Die Cutter, a 50 inch x 80 inch machine. This being a totally new technology, Ward also had to develop the dies to support the process. When asked the key to the success of the machine, he replied that he built a machine that was “twice as strong, ran three times as fast and cost half as much as the competition.” The legacy of Ward continues today under those same key principles. Recent developments such as the Direct Servo technology in the ServoGrafix Die Cutter provide the highest level of accuracy, simplicity and robustness.

Today MarquipWardUnited is combining a rich and innovative heritage with new creative technologies to provide unique solutions for the corrugated industry.

Acknowledgements: Christine Lyall, BCI 50 20th Century Leaders of the Box and Carton Industry, A Boxboard Containers International Special Report.

Our Company Culture

As part of the Barry-Wehmiller organization, we’re proud that the solutions we provide help bring many of life’s daily necessities to people across the globe. But that’s just what we do. What truly defines us as a business is how we do it, and that’s by fostering a caring, trusting, nurturing organizational culture through which people feel safe to express their ideas and share their gifts and talents.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)