MarquipWardUnited Sheeting

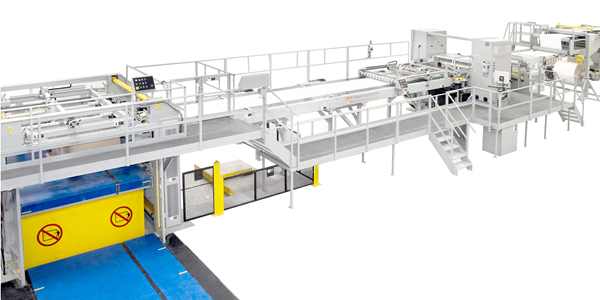

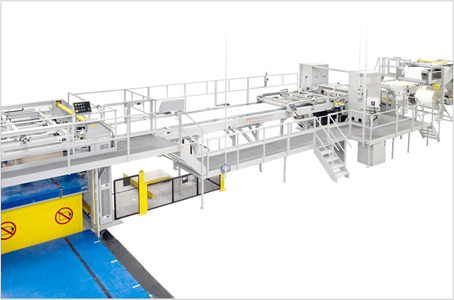

MarquipWardUnited Folio-Size Sheeters

On a worldwide basis, MarquipWardUnited offers mid-range and economical sheeters for paper, board, laminates, plastic, fabric and foil in the industries of paper mills, folding carton plants, and convertors. These sheeters offer flexible configurations to suit small, medium and large plants and all include our legendary knife technology.

SheetWizard 1650 (65 in) / 1850 (73 in) Dual Rotary Sheeter

The SheetWizard Dual Rotary Sheeter offers flexible and cost-effective configurations to suit many converters, folding carton plants, and mills. It runs both paper and board, providing superior cut quality and accuracy, featuring a unique dual-rotary knife.

SheetRunner 1850 (73 in) Dual Rotary Sheeter

The SheetRunner is a dual-rotary sheeting system for folding carton plants and commercial printers. Optimized for high-volume board production, this machine features brushless, liquid-cooled, high-torque knife cylinder motors to reduce maintenance and lower power consumption.

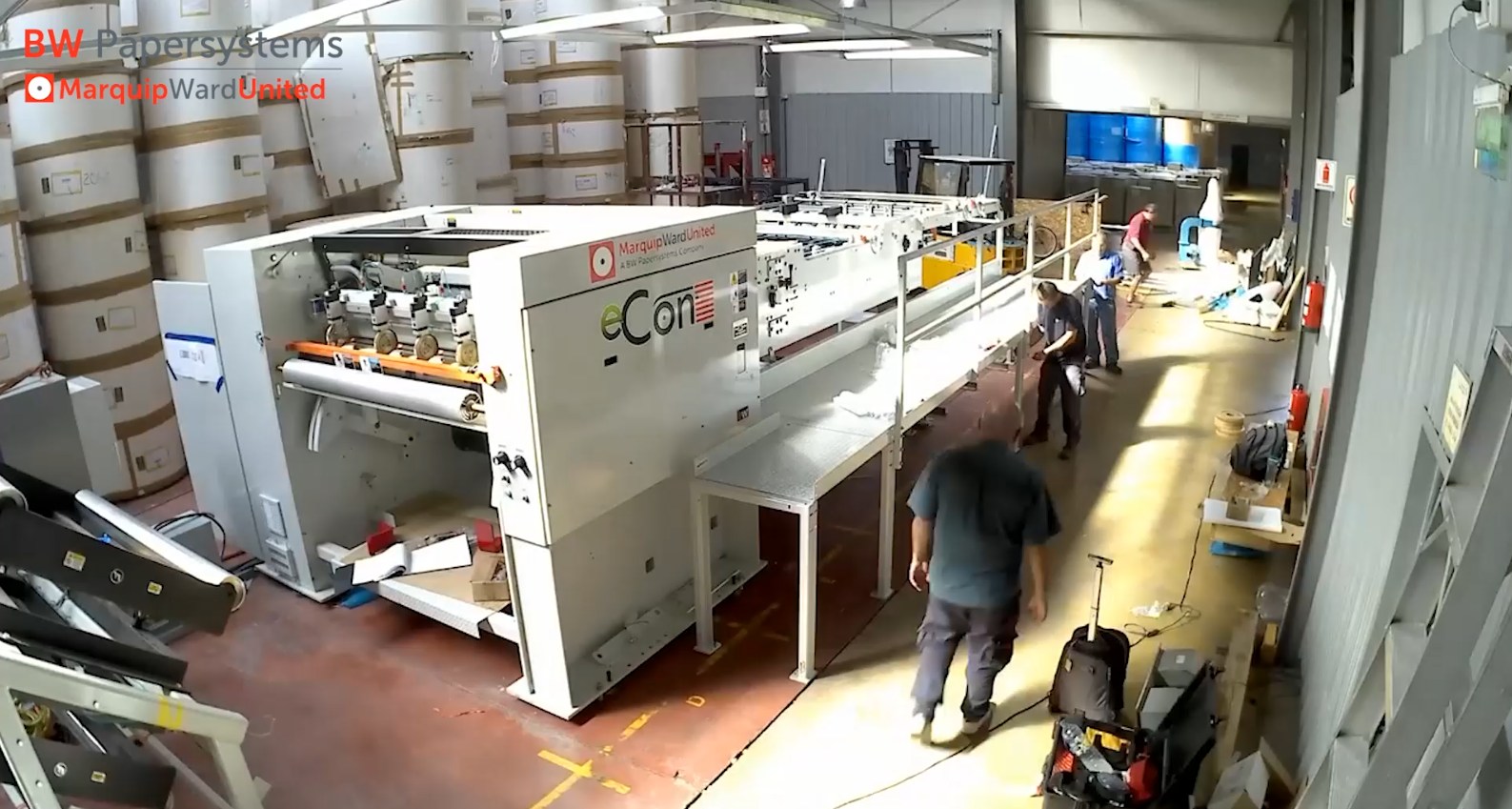

eCon Sheeter - Installation timelapse at customer Corti, Argentina

The MarquipWardUnited eCon Sheeter is a world-class machine. It’s not only easy to operate and maintain but it's also easy and quick to install. It takes a little bit longer than in this timelapse though... Enjoy and watch the eCon sheeter being installed at our customer Corti in Argentina.

Watch VideoUpgrades

With our extensive experience, we have developed a wide variety of upgrades and Technical Improvement Programs to keep your BW Papersystems equipment prepared for future production demands.

The Technical Improvement Program offers a catalogue of standard upgrades for attractive conditions.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)