Successful Relocation of a Pre-Owned Folio Sheeter

A new home for a Jagenberg folio sheeter...

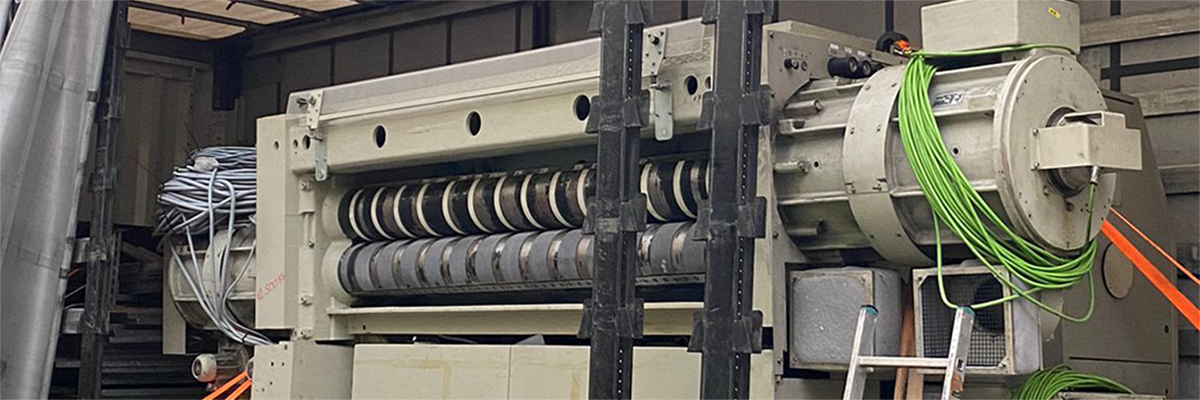

A Jagenberg sheeter, type SYNCHRO 400-2200 DD2, with SPEEDPILER and SPEEDWIND unwinding devices for 6 reels, built in 2004, needed to be moved from Germany to Slovenia as a pre-owned machine. For the necessary disassembly and reassembly at the new location, the Value Stream Field Service of BW Papersystems' Hamburg site presented the customer with a customized offer.

Compact units and sequenced delivery for smooth reassembly

BW Papersystems was able to score points with the customer thanks to simple, functional solutions for the complex task. For example, the sheeter was dismantled into compact units to make maximum use of the loading area during transport and reduce the number of trucks. In addition, timed delivery in the correct sequence enabled just-in-time reassembly. Overall, all planning of the necessary work steps was carried out with foresight and hand in hand with the customer.

Thanks to a thorough inspection of the Jagenberg sheeter already during disassembly, the experts from BW Papersystems were able to offer necessary spare and wear parts. As an OEM for Jagenberg sheeters, BW Papersystems has the complete documentation for the machine. All the necessary parts, including the required foundation material, were thus available for reassembly and a smooth process was guaranteed.

On-time installation and commissioning

After successful commissioning, the customer was able to start production on schedule on the more than 18-year-old machine. The result: a highly satisfied customer who is already thinking about the next optimization steps together with BW Papersystems as a partner.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)