The 6 Different Types of Folding Cartons

Folding cartons have a lot of benefits. They’re flexible, easy to produce at speed in large quantities, and durable enough to provide products with extra protection. But not all folding cartons are created equal. Different types of folding cartons are meant for different types of products. In this guide, we explore each of the different types of folding carton packaging and how they can help your business achieve its goals.

The Different Folding Carton Styles

In general, there are six common folding carton styles.

Each different style has its own advantages and disadvantages for certain products.

These folding carton types are:

- Reverse tuck box

- Straight tuck box

- Auto-lock bottom box

- Snap-lock bottom box

- Two-piece boxes

- Paper sleeve packaging

Reverse Tuck Boxes

- Arguably one of the most common folding cartons on the market.

- So called because the closures tuck in at opposite ends.

- The top closure tucks from rear to front, and the bottom closure tucks from front to rear.

- These cartons are extremely easy to assemble and store flat reducing the floor space cost during the manufacturing process.

- In addition, these folding cartons are easy to load with product.

- Reverse tuck boxes are best suited for light or medium-weight products.

- The one big downside is these boxes have a visible seam at the ends where the flaps connect because of the way they are built, making them less pleasing to the eye.

- These boxes are used in plenty of different industries, including electronics, pharmaceuticals, and cosmetics.

Straight Tuck Boxes

- Similar to reverse tuck boxes, they share many similar traits with them.

- The key difference is the closures tuck in on the same side.

- This actually provides an additional benefit because you can create more folding cartons from a single paperboard sheet.

- This means straight tuck boxes are more cost-effective.

- Additionally, because both flaps tuck in on the same side, the folding carton design is more pleasing to the eye and avoids raw edges visible on the front of the box.

- Other than that, they fold flat and are easy to store and assemble similar to reverse tuck boxes.

- These folding cartons are also best suited for light to medium-weight products and are used for electronics, pharmaceuticals, and cosmetics products.

Auto-Lock Bottom Boxes

- These boxes are characterized by a specially designed bottom that automatically locks into place when the folding carton is assembled.

- The top usually consists of a simple folding tuck top.

- The auto-locking bottom makes the folding carton the sturdiest of all types.

- This means the auto-lock bottom box is perfectly ideal for heavier products.

- In fact, this box is often used for heavy food items like wind bottles, large toys, hefty pharmaceutical containers, and large cosmetics.

- The biggest downside of this box is it’s more expensive than other types of folding cartons because it needs an extra step to glue the bottom closed during manufacturing.

Snap-Lock Boxes

- This type of folding carton gets its name from the bottom flaps that snap into place and lock on assembly.

- It’s also sometimes referred to as a 1-2-3 bottom box in reference to the steps it takes to assemble it.

- Like the auto-locking box, these cartons are heavy-duty and suited for larger products.

- They also work great for retail because the flat bottom sits easily on store shelves.

- Prior to assembly, it can also be stored flat to minimize floor space in the manufacturing process.

- One of the bigger downsides of this kind of folding carton is it can be a bit expensive to produce, but making them in large volumes can help offset the cost.

- It’s also still less expensive than an auto-lock bottom box because it requires fewer steps to assemble.

Two-Piece Boxes

- Two-piece boxes consist of a top and bottom half that fit together to form the packaging.

- When these two halves fit together, they form a double-walled package.

- This gives fragile products inside an extra layer of protection.

- This is why these boxes are often used for things like clothing, jewelry, baked goods, and other luxury items with fine details that could get damaged easily.

- You’ll most likely see this folding carton being used in the retail industry.

- These boxes can be stored flat to minimize floor space.

- They also hold up really well in store displays.

- Two-piece boxes are best suited for lightweight products due to their design.

- The downside of these boxes is that they may take longer to manufacture and can be more expensive because you need to make both the top and bottom halves prior to assembly.

Packaging Sleeves

- A packaging sleeve is essentially a folding carton that doesn’t have either a top or bottom closure.

- Instead it’s meant to be slipped over an existing box to allow for additional product design or messaging.

- One of the biggest reasons to use this folding carton is if you need to customize a product.

- Packaging sleeves are highly versatile and can be used to instantly give your product an iconic look.

- Because they use the least paperboard out of all the folding cartons on this list, they are also the most cost-effective.

- You can find these folding cartons being used in many different industries as they work well on most types of packaging.

- The big downside is it doesn’t offer that much protection to your product and requires a separate box to already be in place to work.

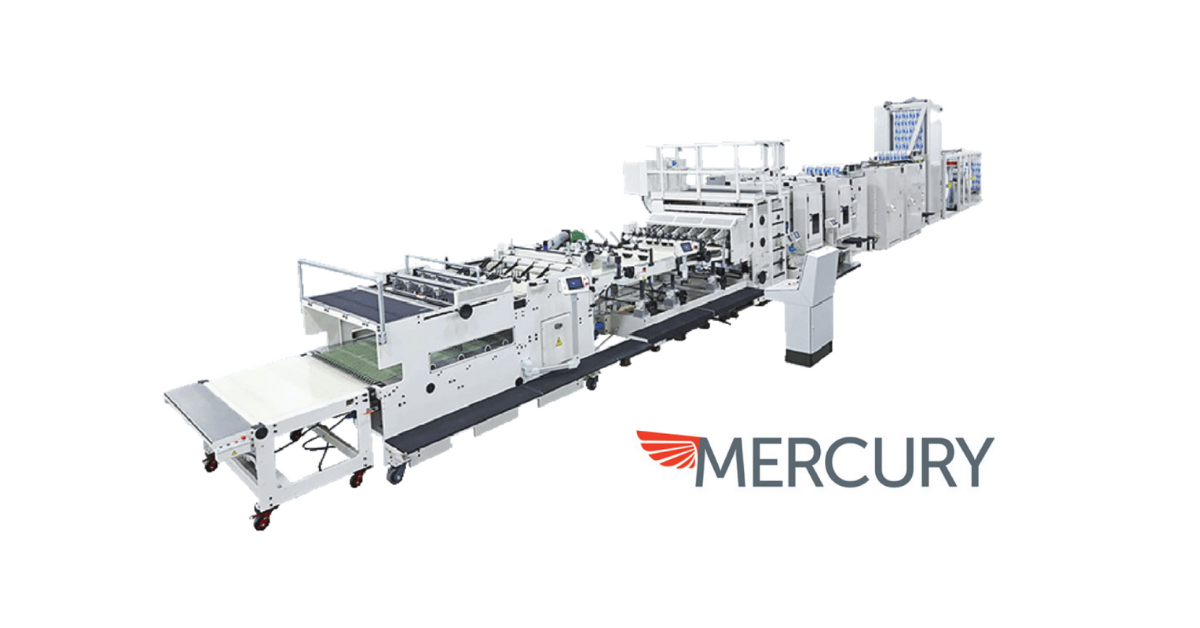

Become a Folding Carton Powerhouse with BW Papersystems Equipment

- BW Papersystems is one of the leading providers of folding carton manufacturing equipment in the world.

- Are selection of folio-size sheeters and web-fed platen die-cutters is an industry benchmark in both speed and efficiency.

- Our machines can reduce operation steps by over 50% and offer the fastest way to produce a folding carton.

- BW Papersystems equipment can handle a variety of folding carton needs and offers constant support.

- Whether you need troubleshooting due to a stoppage, in-house training to prepare your team, or remote diagnostics, our highly skilled and factory-certified personnel are here to lend a hand.

The Ultimate Folding Carton Machine: Zerand Web-Fed Platen Die Cutter

- Check out our Zerand Web-Fed Platen Die Cutters – it’s your go-to for efficient folding carton production.

- With reels in play instead of sheets, this machine gets folding cartons printed and ready in record time.

- It delivers up to 2.5 times the output of regular sheet-fed platen cutters with the same impressive quality output.

- Thanks to our nesting approach and elimination of gripper margins we have reduced board usage by up to 18%.

- Plus, with its compact and automated setup, our Web-Fed Platen Die Cutter takes up less

space and needs fewer operators so you can get more done and save on costs. - Need more options for folding cartons?

Browse through BW Papersystems’ other folding carton equipment, including folio sheeters and more!

Why Choose BW Papersystems for All Types of Folding Cartons?

- At BW Papersystems, we don’t just sell equipment to help you tackle a tough production job.

- We partner with you to make your production line the best you can be.

- It starts with expert installation.

- Our factory-trained and certified equipment experts will help you integrate your custom folding carton machine seamlessly into your production line.

- Our customer relationships go much deeper than a purchase.

- You get constant support from BW Papersystems.

- Whether you need in-house equipment training, a production line audit, or help troubleshooting a breakdown, we’ve got you covered.

- That’s just part of what sets BW Papersystems apart as a world-class paper finishing equipment manufacturer.

Get in Touch with BW Papersystems Today!

- No matter which types of folding cartons your line is working with, BW Papersystems can help you make them faster and better.

- Get in touch with one of our equipment experts today and we’ll discuss the best options for your line and particular manufacturing job.

Folding Carton

Talk to a BW Papersystems' Folding Carton expert to find our about what machine is the best solution for you and your folding carton production process. We can even conduct trials or provide output calculation to see potential improvement opportunities.

Contact us to learn more about how we can support your Folding Carton business

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)