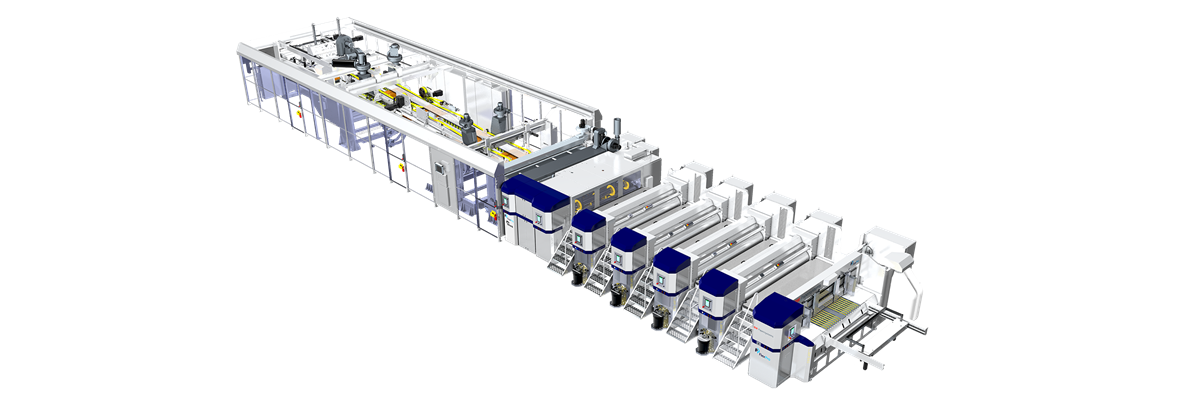

In the world of corrugated box manufacturing, efficiency, quality, service, and cost-effectiveness are key factors in the decision-making process. FlexPro, the new family of Flexo Folder Gluer (FFG) from BW Papersystems is the ideal solution for box manufacturers requiring quick setup as well as long runs; it offers unmatched efficiency in setup, productivity, user experience, and maintenance.

BWP understands the unique challenges our customers face in their day-to-day operations. BW Papersystems New Product Development team has designed the FlexPro FFG to address the specific needs of the global market.

“We want to provide our customers in EMEA with a better customer experience, so we have increased our manufacturing, service and parts in our Germany location. The FlexPro meets our customers' expectations of performance and low cost of ownership,” said Mark Taylor Director of Sales EMEA.

"Our customers have asked for a machine manufactured and supported in North America that will meet or exceed our competitor’s performance and have a lower annual cost of ownership. The FlexPro meets these needs to transform our customers’ production line and increase profitability,” said Pete Bickford, Vice President of Sales, North America.

The FlexPro is designed with ease of maintenance in mind. Key components are accessible from both sides, and the equipment sections can be easily separated with the push of a button providing easy and safe accessibility for housekeeping, maintenance, belt replacement and more. The advanced HMI with its intuitive interface further simplifies operation and troubleshooting.

“In today’s environment, uptime thus performance is critical. The FlexPro product family is the most accessible SWR Flexo-Folder-Gluer in the market.” said Steve Biller, Director of Product Management. “This is the most user-friendly machine we have ever built. Although set-while-run for job-to-job changes, the FlexPro can fully open and close every section of the line in minutes, minimizing the biggest challenges operators and maintenance personnel face day to day ”.

With production speeds of up to 300 sheets per minute on the 12.29 model (50”x113”), the FlexPro ensures that manufacturers can meet high-demand orders with ease. When paired with BW Papersystems Twin Box Slitter (TBS), productivity doubles to 600 boxes per minute. This efficiency translates to improved productivity and increased profitability. Set-While Run capability is a proven process to reduce setup time thus increasing efficiency. Although designated as a SWR FFG, the product output speed and potential for combining the FlexPro with the TBS offers unparalleled productivity on long run orders.

The FlexPro was designed with safety on the forefront. With state-of-the-art Safety PLC and RFID safety key switches, along with ergonomics and safety considerations beyond compliance, the FlexPro provides peace of mind for manufacturers operations.

Designed in two sizes to meet customers’ needs, the FlexPro 12.29 model up to 300 sheets per minute and The FlexPro 9.25 (37.5”x 96”) model up to 400 sheets per minute, provide customers the ability to run a wide array of box sizes. Combined with other available options, the FlexPro is positioned to transform how manufacturers produce high-quality corrugated boxes in large volumes and at high speeds.

The FlexPro Flexo Folder Gluer is loaded with advanced features that benefit box makers with performance and reliability. This next generation design includes:

Variable stroke feeder: The FlexPro’s fully independent variable stroke feeder enables precise control over feed rates, accommodating different box sizes and configurations. This precision ensures optimal performance across a wide range of sheet sizes and compositions, ensuring consistent output regardless of paper weight, finished box size, and less than optimal board.

Set-while-run printing: Setting up the next job’s print plates while running allows for continuous production without the need to stop the machine. This top printer significantly reduces downtime, increases throughput, and ensures that manufacturers can maximize productivity. Each print section comes with an auto locking system for the printing plates without the need for tools, and Carbon Fiber chamber doctor blade system. This along with the exceptional color to color registration that the BWP vacuum transfer system provides, manufacturers can expect exceptional print quality and performance

Four shaft slotter with two-up capability: The four-shaft dual slotter allows for precise scoring and slotting, with the ability to create center slots on two-up boxes without the need for a cutting die or a secondary slotter. This feature streamlines production and reduces the need for additional tools and setups. Production can double with small boxes when combined with a Twin Box Slitter from BW Papersystems.

Die cutter with mechanical scrap ejection system: BWP is known for their industry-best rotary die cutters and understands that the need for die cutting on FFGs is increasing. The FlexPro is designed to address todays and tomorrow’s die cutting needs. The variable speed anvil with SHARK anvil trimmer ensures precise trimming for accurate die cutting. Included with the SHARK anvil trimming system, a vacuum system is provided to remove the trimmed urethane preventing potential contamination of the boxes.

Fully automated Down-folder with advanced scrap handling: The FlexPro folder is equipped with an independent scrap handling section ensuring scrap free boxes. The down folder is fully automated eliminating the need for manual adjustments between setups. Additionally, the independently servo driven folder belts offer the ability for skew adjustment to produce perfect boxes.

Advanced counter ejector: The newly designed counter ejector offers the ability to produce bundles and boxes with less crush, less jams; while offering better accessibility, and less moving parts for reliability and ease of maintenance.

Advanced human machine interface (HMI): The FlexPro features a modern control system with multiple advanced consoles. The full HD Windows touchscreen and flexible swing arm design make the interface user-friendly and accessible. Advanced diagnostics capabilities further enhance the machine’s reliability and ease of operation. The FlexPro HMI architecture allows for the use of remote handheld devices for ease of maintenance.

The FlexPro family of products is a game-changer for the corrugated box manufacturing industry. Its combination of high-speed production, quick setup, die cutting, exceptional print quality, and cost-effective operation makes it the ideal choice for manufacturers globally looking to stay ahead of the competition. With tailored solutions for different regions and a strong support network, the FlexPro is set to become the cornerstone of efficient and reliable box manufacturing.

The FlexPro is the newest addition to the BW Papersystems Finishing line that includes the GGX family of flexo folder gluers and rotary die cutters, the ServoPro rotary die cutter, and the MaxPro family including the high yield rotary die cutter. For more information visit bwpapersystems.com.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)