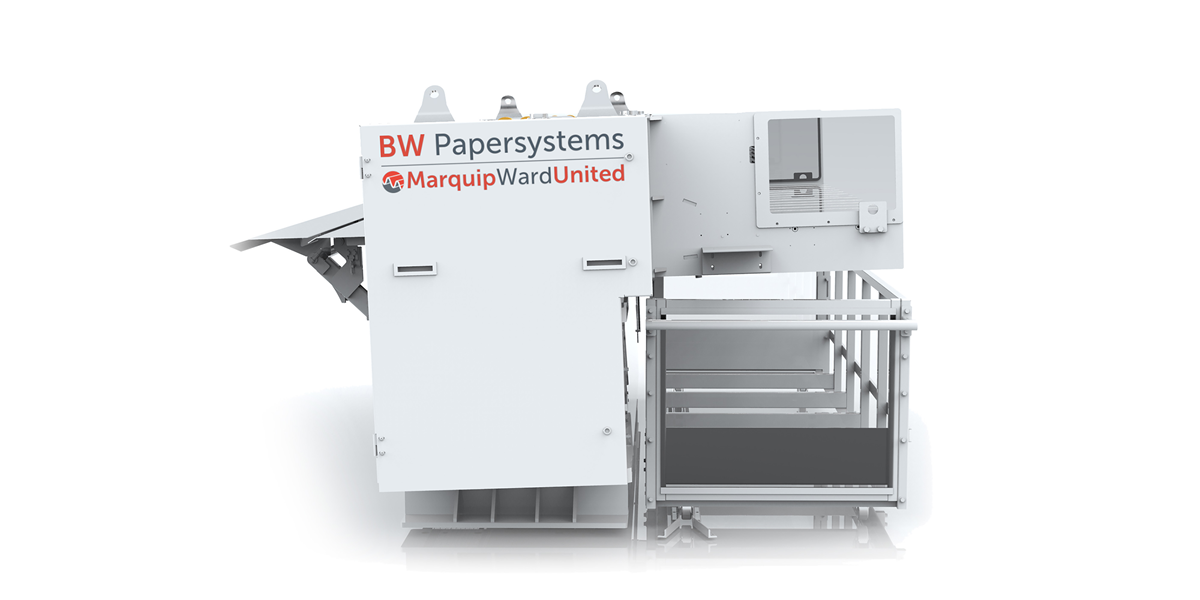

SE1000 Dual Rotary Shear Machine

Product Description

The Shear can enhance the productivity of the entire line through reliable, high-speed

removal of scrap and looseback before it can enter the dry end. Unbounded board is a

frequent cause of dry end machinery jams. Shear features which allow excellent scrap out

reliability include:

- Dual rotary design allows the shear to easily cut through all types of scrap

- Driven diverter nip ensures positive diversion of defective sheets onto the scrap cart. This feature is essential to control board that is not cured properly

- Exit brush prevents looseback accumulation around knife cylinders

- Scrap cart moved closer to cutting cylinder to maximize scrap cart capacity and prevent sheet hang-ups during cart removal.

The Shear can enhance the productivity of the entire line through reliable, high-speed removal of scrap and loose back before it can enter the dry end. Unbounded board is a frequent cause of dry end machinery jams.

Product Features

Perfect for scrap removal or order change web severing. Low diverter angle improves divert reliability. Synchronized to order change control system. Dynamically balanced helical-wound blades on top and bottom knife cylinders.

Scrap Removal and order Change

Low diverter angle and divert reliability

Order Change Synchronization

Dynamically balanced helical wound blades

| Shear | Sever Web | Divert |

| 2500mm (98,4") | 350mpm (1150fpm) | 300mpm (1000fpm) |

| 2850mm (112") | 300mpm (1000fpm) | 260mpm (850fpm) |

SE1000 Dual Rotary Shear Machine

Compare With

- Low diverter angle improves divert reliability

- Scrap cart can be easily emptied with fork truck.

- Parts interchangeable with MarquipWardUnited cutoff knife (knife blades, cylinder motor, and drive).

- AB CompactLogix PLC Controls Platform.

- New frame positions scrap cart upstream for improved scrap stacking and unobstructed cart removal.

- Divert Nip enhances scrap handling.

- Helical-wound blades on top and bottom knife cylinders produce a square cut. This allows the user to make a sellable first sheet on every order change without the waste of a first trim cut. This decreases waste, and keeps small scrap sheets out of the dry end. It also allows for square dunnage sheets when needed.

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)