Machine Model for Improvement

Pemco packaging machine Model 32, 34, 34HS, 37, 37HS.

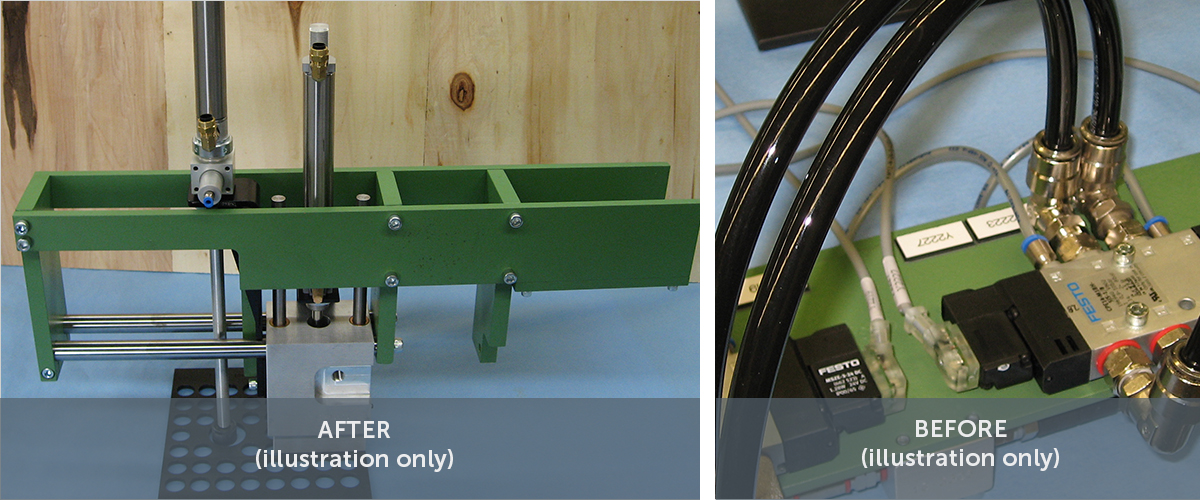

Description of Improvement

This upgrade is part of the Technical Improvement Program (TIP); it includes installing a cylinder that extends through a

slot in the cover plate near the wrap line. This cylinder has a rubber foot that holds the wrap against the ream as the ream is brought to the folding position by the elevator. This upgrade comes equipped with four (4) solenoids mounted on a cross bar across the machine top: Up, down, high pressure, and low pressure. During the folding sequence of the ream, this cylinder is extended down using high pressure to ensure quick response time at higher speeds. Once the cylinder is down, the pressure is switched to low to allow the cylinder to move up with the ream as the elevator goes up. Once the cycle is complete, the cylinder switches to high pressure on the way up to get ready for the next ream. Two supplied regulators allow the operator to set the desired high and low pressure operating points. The set points are adjustable behind the password of the touch screen. This upgrade includes all the required mounting hardware, brackets, air fittings, airlines and other required electrical and mechanical parts. The wrapper sheet holder cylinder is equipped with an air clamp that prevents the cylinder from drifting down in case of air loss or manual machine rotation.

Benefits

- Prevents the wrap from shifting on the ream and misaligning

- Aids in running wrapper material of varying characteristics

- Improved sheet position gives a better, more consistent ream appearance, especially in registered wraps

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)