TIP 030-0430 Inverted External Girth Glue Upgrade

Machine Model for Improvement

Pemco packaging machine Model 39SDescription of Improvement

This upgrade is part of the Technical Improvement Program (TIP); it converts the machine from internal glue sealing to external glue sealing.

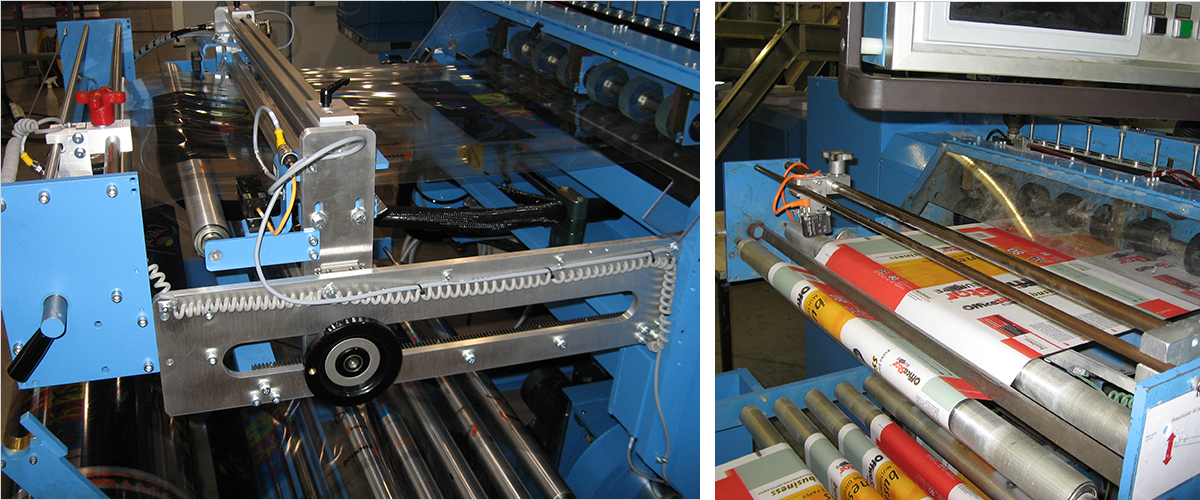

This is accomplished by installing a new external girth glue gun assembly prior to the feednip rollers. The gear rack is used to position the glue gun to achieve the desired stripe position on the wrapping sheet. As the sheet starts to feed, the glue gun gets activated along with the cooling air gun. It is critical to get the glue cold prior to going into the feednip to ensure no contamination. Once the ream is wrapped, the girth seal conveyor reheats the glue as the ream goes through it. This finally seals the ream shut.

This improvement also includes a new longer glue hose. The newly supplied horseshoe sensor ensures glue is applied only if it is blocked by the wrapping sheet. The included sliding mechanism allows the gun assembly to be moved out of the way for poly application or maintenance.

Benefits

- Reduces overall glue build up and change over time

- Eliminates possible glue contamination on the bottom sheet of the reams

- Much thinner stripe keeps folding section cleaner for better wrapping and saves glue consumption

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)