TIP 160-0402 Hopper Chain Coupling Upgrade

Machine Model for Improvement

Pemco packaging machine Model 161, 161HSDescription of Improvement

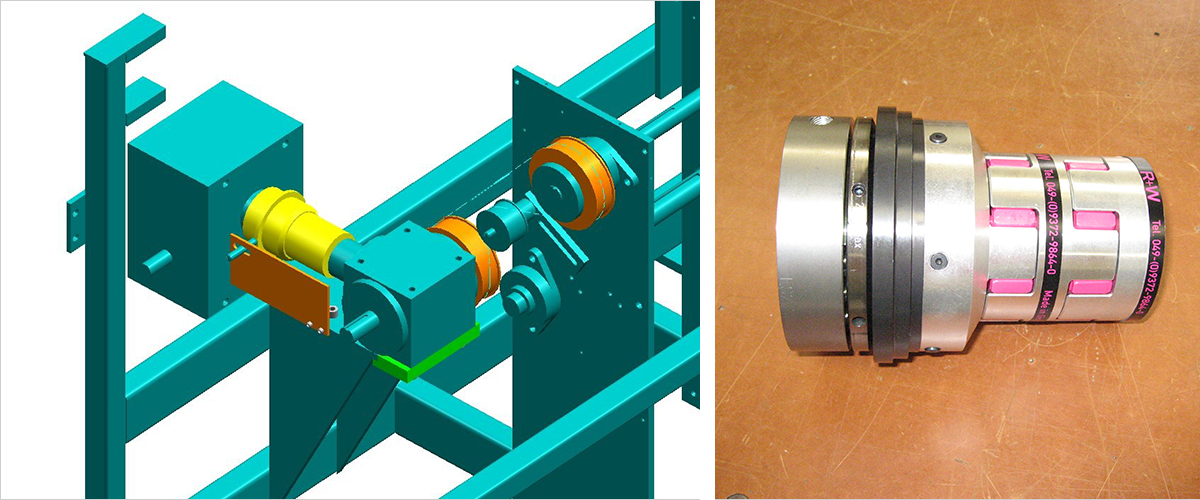

This upgrade is part of the Technical Improvement Program (TIP); it replaces the existing hopper chain coupling with an overload coupling. This overload coupling will disengage and shut the machine down when a jam is detected, preventing damage to the hoppers.

The disengagement of the coupling will also prevent the hopper timing from changing. A new shaft, spacer for the gearbox mounting and a belt are supplied in order to fit the new torque coupling.

As part of this TIP, the limit switch that was used with the older coupling will be replaced with proximity switch and associated hardware.

Benefits

- Eliminates the need for retiming of the pick-up arms after a heavy jam

- Eliminates chain coupling slipping caused by jams

- Prevents possible damage to the vacuum cups

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)