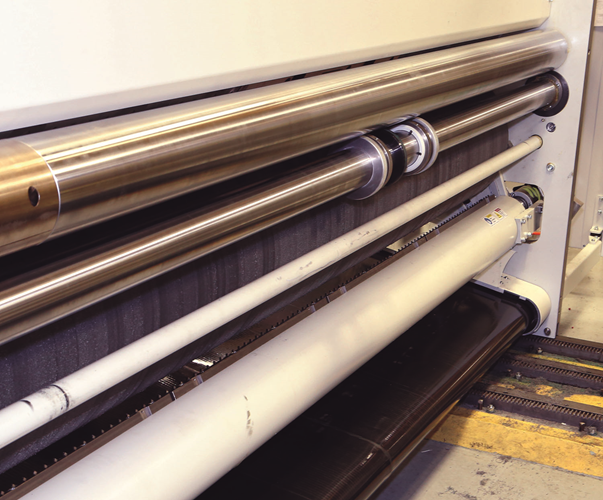

Shark Anvil Trimmer

Beneifts

- A current customer saw, “Over 90% reduction in anvil-related downtime in nine months following the Shark installation!”

- The Shark system is engaged while machine continues to process board, meaning no stoppage is required to trim the anvil blanket.

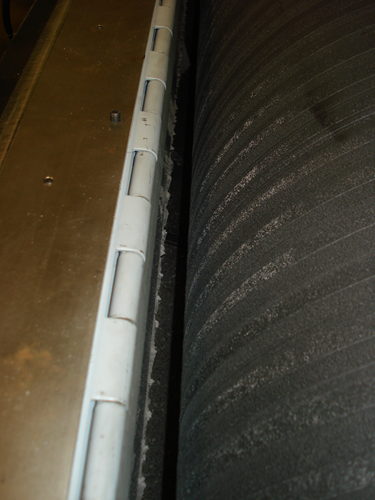

- Unlike other systems, the Shark does not generate heat from the anvil covers. You can trim more frequently without urethane gumming.

- For heavy die cuts, the Shark trims more frequently, minimizing blanket height variability to ensure optimal die cut impression. This can mean up to 50% cost savings in anvil covers!

- One facility found, “66% increase in impression/set” in the six months following the Shark installation.

- The precise grinding reduces the frequency of anvil rotations. Longer intervals between rotations saves forty (40) minutes during preventative maintenance procedures.

Pricing, Installation, and Delivery

Contact your BW Papersystems Regional Product Support Manager or Regional Customer Support Office for pricing and delivery.Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)