TIP F 1420 Draglink Gear General Overhaul

Machine Model for Improvement

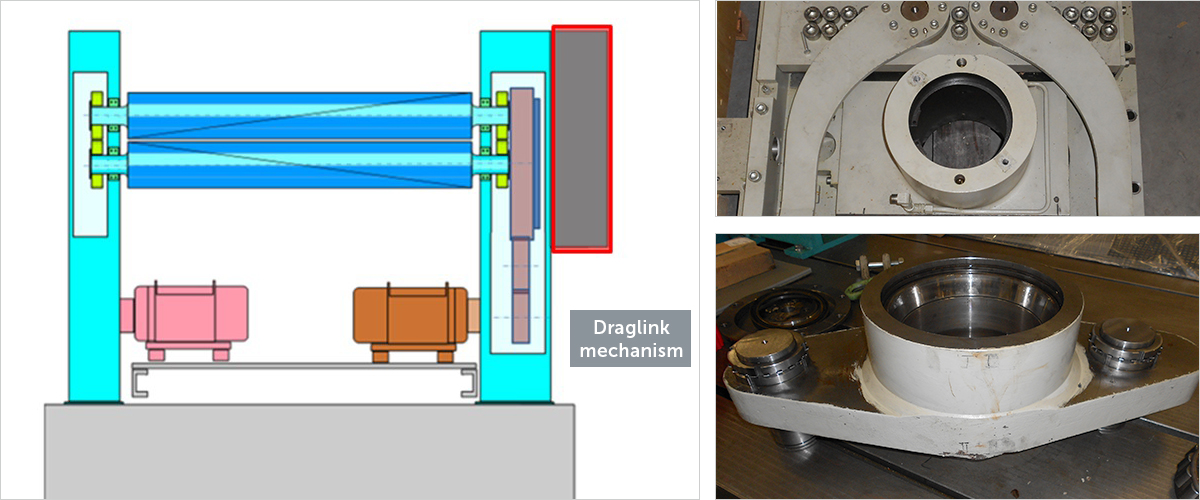

All Jagenberg sheeters with draglink mechanism

Description of Improvement

knife life becomes shorter, cut quality deteriorates and oil leakages can occur.

This TIP module provides a complete overhaul of the draglink gear at the BW Papersystems facility in Germany, where all the required special precision machinery, tools, measuring equipment and expertise are available.

The exchanged bearings and parts of the draglink gear cause less vibrations and reduced noise emissions. The new bearings at the double lever (see picture) allow an improved sheet length accuracy.

During a general overhaul the draglink gear unit is completely dismantled, thoroughly checked, cleaned and all wear and tear parts will be replaced. All the mechanic guide rails and guide plates of the draglink mechanism will be overhauled in our in-house machine shop.

The general overhaul package does not include new knife shafts and new draglink gear wheels.

Benefits

- Improved operational availability and improved sheet length accuracy

- Smoother machine running with reduced noise emission and vibration

- Exchange of all wear & tear parts reduces maintenance costs

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)