TIP F 1440 Replacement of all Solenoids of the Basic Machine by a New Solenoid Terminal

Machine Model for Improvement

All Jagenberg sheeters with single valves for the function of the basic machine

Description of Improvement

Over time, after years of intensive daily, around the clock production, the reliability of the valves has been drastically reduced. An unexpected production stop is likely. The production of the original type of solenoids has been discontinued since many years and are not available anymore as a spare part.

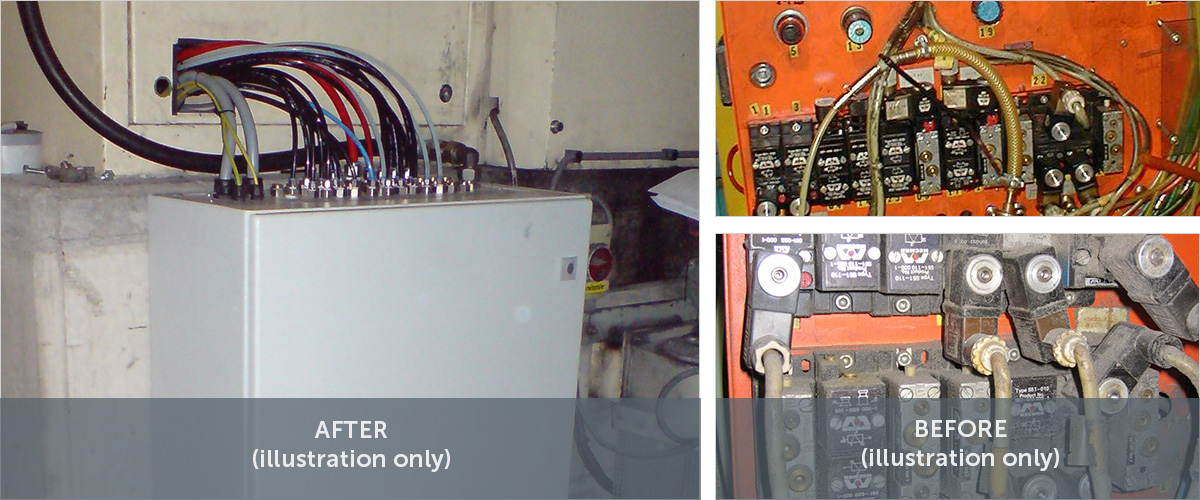

This upgrade from the Technical Improvement Program (TIP) replaces all the single obsolete solenoids and pressure switches of the basic machine by a new solenoid terminal. The solonoid terminal is responsible for the functions of the web clamp, draw roll, drag link clamp and brake.

The new solenoid terminal, including pressure switches, will be installed in a separate new small cabinet and mounted at the basic machine. The pneumatic tubing to the actors and flexible cable trays will remain unchanged.

This upgrade increases the reliability of the sheeter. With the latest technology of the solenoids the maintenance effort of the slitter section will be reduced and spare parts availability is ensured.

Benefits

- Spare parts availability and latest technology due to the elimination of obsolete parts

- Less maintenance

- Solenoids are mounted in a separate cabinet

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)