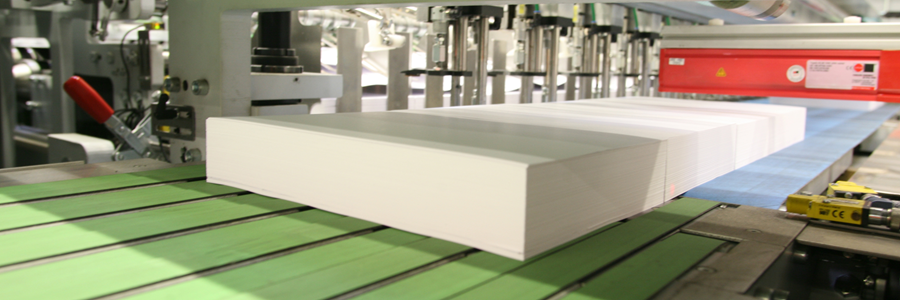

Model 137HS Ream Stacker and Accumulator

Product Description

- Exceptional control of ream stacking process

- Up to 150 reams per minute can be stacked

- LIFO or FIFO configuration possible

- Logic control to monitor production & to divert stacks to accumulation belt if needed

- Automatic back feeding of accumulated stacks in line

- Smooth product handling due to motor controlled axis

- Touchscreen interface

- Options include lift and turn unit, accumulator bed options and several capacity options

- All converters of standard U.S. and metric paper ream sizes

Product Features

The Model 137HS ream stacker/accumulator precisely stacks of U.S. and metric size reams to preset height and ensures smooth product handling and exceptional control including diverting stacks to an accumulation belt when necessary. It is available as a last-in/first-out (LIFO) or a first-in/first-out (FIFO) configuration.

Precise Case Stacking

Flexibility

Accumulating System

Simple Operation

| Metric | Imperial | |

|---|---|---|

| Package size range | 175 - 470 mm (length) 195 - 355 mm (width) 10 - 90 mm (height) | 7 in - 18.5 in (length) 7.6 in - 14 in (width) 0.4 in - 3.5 in (height) |

| Maximum stack height | 460 mm | 18 in |

| Production Speed | up to 150 reams/minute | |

Full control in stacking of up to 150 reams per minute

The Model 137HS ream stacker/accumulator is available as a last-in/first-out (LIFO) or a first-in/first-out (FIFO) configuration and provides exceptional control in stacking standard U.S. or metric ream sizes. An accumulator belt ensures that stacked reams can be diverted if production stops and be fed in again once it resumes.

Simple operation with touchscreen interface

A touchscreen simplifies machine operation. The Model 137HS is a self-contained machine with PLC and its open design allows for complete access and easy maintenance.

Stacker system with single or double stacking capability

The belt infeed conveyor is driven by an electric motor. A cam-operated ream pusher carefully moves the reams towards elevator system. The descending elevator stacks reams to preset height. It offers both single and double stacking capability.

Accumulating system and conveyor

System solutions for ream stacker/accumulator Model 137HS

- WillPemcoBielomatik cut-size sheeters (e.g. SLK Procut (2-6) pockets)

- Further WillPemcoBielomatik packaging machines

- Ream wrapper

- Ream labeler

- Ream inspection/rejection

- Case labeler

- Case inspection/rejection

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)